To explore what makes family businesses resilient and sustainable across generations, Family Business Alliance invited three seasoned leaders to share their insights on legacy, innovation, governance, and next-gen readiness.

- Betsey Fortoulis, Director of Partnerships and Development, Family Business Advisor at InnerWill

- Robin Burns, Director, Family Business Alliance

- Randy Boss, Co-founder of Emerge Apps and Chairman, Family Business Alliance

Q: From your research and experience, what are some of the most significant, often unseen, strengths that family ownership brings to a business?

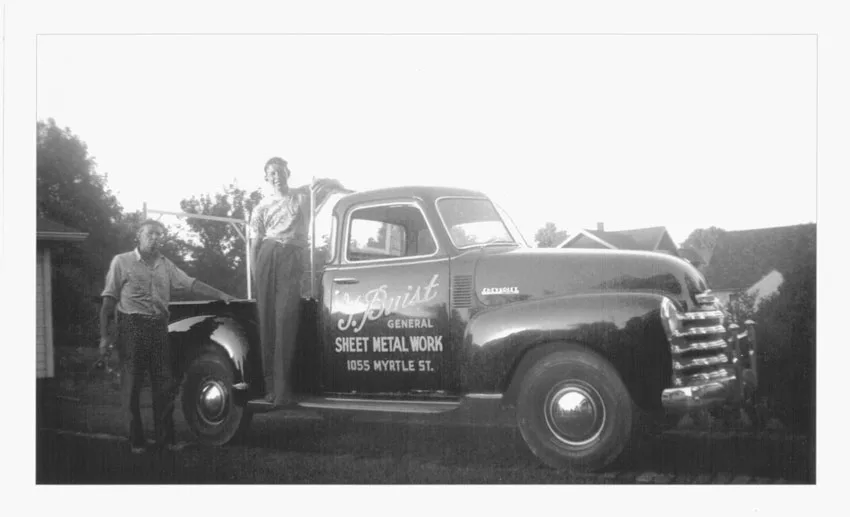

Robin Burns—For many, business is an extension of the family. This emotional connection leads to extraordinary levels of dedication, especially during difficult times. Unlike corporate environments, family members are more likely to make personal sacrifices, show up on the “front lines,” and roll up their sleeves to ensure success. This deep-rooted loyalty can also extend to their employees. When employees see family members committed to the business in the day-to-day, they often develop a strong sense of belonging and loyalty themselves.

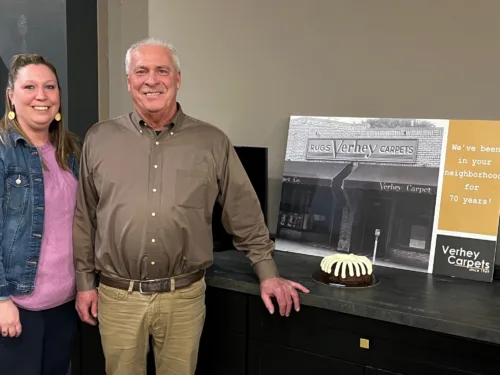

Betsey Fortoulis—In a rapidly changing world, the family often represents a source of consistency and continuity in a family enterprise, providing a strong foundation and a long-term perspective. This can be particularly valuable as external factors and market conditions shift, offering a stable element amidst the turbulence and ambiguity.

Values also have a multigenerational impact. We pass them on to our children, and our children’s children. Therefore, when families align around values and shared purpose, they have secure building blocks for the next generation to honor the legacy of the founder while at the same time having the freedom to adapt and innovate to ensure continued business success during changing times.

Randy Boss—The strength of family business often lies beneath the surface. There’s a level of commitment, trust, and shared purpose that’s hard to replicate elsewhere. You’re not just building something for short-term gain—you’re creating something that matters to the people you care about most. That long-term mindset shapes how decisions are made, how employees are treated, and how risks are taken. At Emerge Apps, our values guide us—not just strategy.

Q: We often hear about the “founder’s syndrome” or the challenges of subsequent generations living up to a legacy. How can current leaders, both family and non-family, work to build a sustainable future that honors the past yet adapts to new realities?

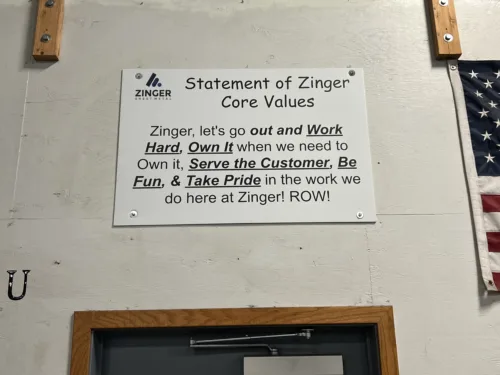

Robin Burns—Founders are often by nature visionary entrepreneurs who built their companies from the ground up, taking significant risks to provide for their families. Their legacy is not only in the enterprise they created but in the values, resilience, and ingenuity they demonstrated. To honor this legacy, current leaders should embrace an entrepreneurial mindset – they need to see themselves not as the caretaker – but as the new founder. By investing in innovation and demonstrating a willingness to take calculated risks – they can honor the original spirit of the business as well as propel it forward. Also, these new leaders should formalize and adopt the core values that guided the founder. By clearly articulating and embedding these values into the company culture – they become the compass for future decision making and evolving business strategies.

Betsey Fortoulis—Many family business leaders are reluctant to shift from a personal relationship with the founder to a more formal relationship with a successor. Most of these leaders have developed unique ties with the founder that extend well beyond the parameters of a typical working relationship. We would encourage leaders to ensure that their strategy is focused at the enterprise level, rather than at just the business level. The three circles (Ownership, Family, Business) are interconnected and their missions, visions, values, and goals should be aligned, consistent and mutually supportive.

Randy Boss—Founders have to learn to let go—but not disappear. That’s a tension we all face. It’s about making room for the next generation to lead while still being available as a mentor and sounding board. I’ve found that when you focus more on principles than control, the business can grow beyond you. It’s not about preserving the past exactly as it was—it’s about honoring it while giving others permission to evolve it.

Q: The “next generation” often has different perspectives and aspirations. What do you see as emerging trends or concerns from this next generation?

Robin Burns—Technological advancements continue to interface with the business community at an unprecedented and accelerated pace. Recent studies from next-generation leaders continue to express concern about whether their organizations are equipped to adjust and adopt to meet industry innovation. As a result, there’s a sense of urgency to not just catch up, but to build a future-ready foundation that can adapt to constant change through digital infrastructure and data-driven decision-making.

Betsey Fortoulis—The pace of change is accelerating, particularly in the realm of technology and global interconnectedness. AI is here, and how to leverage it ethically and effectively is a big concern/opportunity. There is also a much stronger focus on well-being and mental health. How do we reward productivity over suffering? Finally, the next gen is very focused on purpose-driven work – making it more important than ever to clarify an organization’s mission, vision, and values and align them with the strategy, leadership competencies, and processes.

Randy Boss—They see the world differently—and that’s a good thing. The next generation wants purpose, balance, and a workplace that reflects their values. They’re not afraid to challenge tradition if it means better alignment with people and impact. What’s encouraging is that they’re not rejecting the business—they’re just asking, “How can we do this better?” At Emerge Apps, my sons are constantly pushing for better tools, more clarity, and a more flexible approach to work.

Q: It appears like the external and economic disrupters continue to challenge businesses. What internal strengths or strategies can help them to adapt and thrive?

Robin Burns—Look back to move forward. From the early startup days, your family business has never shied away from challenges. Reflect on the tough times—what obstacles did you face, and how did your family and the business respond? What strategies proved effective? How did you adapt and realign the organization to overcome adversity? Many of those same approaches can be applied again as you stay committed to the long game.

Betsey Fortoulis—Back to the fundamentals…what’s your “why”? Leaning into the family legacy and the family as a source of consistency during disruption can be the beacon. When the “why” is clearly defined, the “how” can be easily adapted.

Randy Boss—You can’t control external disruption, but you can strengthen your foundation. Open communication, trust between generations, and a shared vision make it easier to pivot when things change. It’s also about being willing to challenge the status quo—even if that status quo came from you. At Emerge Apps, we’ve always focused on learning fast, staying close to the customer, and being willing to evolve.

Q: Looking ahead, what do you believe is the most critical area family-owned businesses in West Michigan and beyond should be focusing on to ensure their long-term sustainability and success?

Robin Burns—Engagement! Studies demonstrate that legacy and connection to business is a predominant reason for the next generation to join the family business. Many second and third generation organizations do not have formal structures in place. Family meetings and governance programs are the ideal platform to build an engaged next generation (even as young as middle school and high school). Formal governance creates a space to understand family history, mission, and values. Next generation members can begin to build an identity of ownership and accountability to the members of the family and the business.

Betsey Fortoulis—Stay connected with your peers. Family Business Alliance is such an invaluable resource for family-owned businesses in West Michigan and beyond. Learn from each other and share what’s working and not – build a bigger table, not a higher fence.

Randy Boss—Succession and leadership development—no question. Too many businesses stall because they wait too long to plan for transition. It’s not just about choosing the next leader; it’s about building a leadership mindset throughout the family and the company. That takes time, structure, and a willingness to have honest conversations. The earlier you start, the better your chances of sustaining success across generations.

Q: What do you identify as an emerging trend in family business organizations?

Robin Burns—In a rich M&A market, family business organizations are proactively acquiring other family firms to build scale and enhance service offerings. One key predictor of success in acquisitions is acquiring an organization with a similar culture. When values, leadership styles, and long-term vision align, integration is a smooth and sustainable way for growth. We’re seeing this trend not only in local markets but across a national level, as family businesses look beyond their regions to find like-minded partners that support long-term strategic goals.

Betsey Fortoulis—Technology and the digital landscape to help honor family legacies and impact communities for the better.

Randy Boss—Families are becoming more intentional—more governance, more communication, and more willingness to bring in outside perspectives. I’m also seeing a rise in emotional intelligence—people talking about things like identity, conflict, and personal growth, not just ownership and operations. That’s a healthy shift. Families that grow stronger together build businesses that are better equipped to last.

This content has been edited for length and clarity. Email fba@fbagr.org if you are interested in exploring feature opportunities.

Family Business Alliance strives to help family businesses with the tools, resources, and connections to help businesses succeed. Learn more about our resources including Leading Forward, Succeeding in Succession, and Navigating Governance that help to advance family business in our community.