By Pat Soldano

It’s looking more and more like a salvage operation on Capitol Hill as the Tax Cuts and Jobs Act provisions are being examined, culled, embellished, and reconstituted before it expires at the end of next year. But no matter, good, bad, or ugly, there will be a new tax bill in 2025.

As I write this, the House Ways and Means Committee is busy managing its ten Tax Teams to improve or save what it can from the 2017 Tax Cuts and Jobs Act (TCJA).

A few items on the salvage list include avoiding increased income taxes, stopping a decrease in estate tax lifetime exemptions, no increases in capital gains taxes, and restoring research and development expensing, to name a few.

As you may recall, the House Ways and Means Committee Chairman Rep. Jason Smith (R-MO) and Tax Subcommittee Chairman Rep. Mike Kelly (R- PA) formed ten Tax Teams earlier this year to study key provisions in the Trump-era

Tax Teams are set up as follows: American Manufacturing, Working Families, American Workforce, Main Street, New Economy, Rural America, Community Development, Supply Chains, U.S. Innovation, and Global Competitiveness. The stated goal of these teams is to: “help families, workers, and small businesses,” according to Smith.

What Are Key Tax Priorities?

But what are the key family business-oriented tax policies critical for our legislators to review? Our tax team experts on Capitol Hill have uncovered seven “Tax Policy Legislative Priorities” for the 119th Congress that will affect the funeral services industry.

In addition, this month we conducted a spot survey among 100 family businesses asking one question: “what is your number one tax priority?” But first, what are our seven Tax Policy Legislative Priorities? Here they are:

1.Preserve the current tax rates and brackets enacted under the Tax Cuts and Jobs Act. Family-owned businesses rely on the consistency of tax rates more than corporate businesses due to the increased complexity in succession planning. In addition, family businesses are uniquely suited to reinvest more in their business, their employees, and their communities, according to the results of our 2024 Annual Business Survey. In our survey, 52% of respondents indicated that if they paid less in taxes, they would invest more in the business, and 30% indicating they would raise their employees’ salaries.

2. Reduce the estate tax rate. Estate taxes severely hamper the ability for family business owners to pass the business and related assets (which are typically illiquid) to the next generation, making it more difficult for the business to continue growing, providing important jobs, and contributing to local communities. Of family businesses surveyed, 70% have generational employees and 81% have been in operation for 20 years or more. Eliminating the estate tax consistently ranks among the top three priorities.

3. Make permanent the Section 199A deduction for passthrough businesses. The Tax Cuts and Jobs Act included a new deduction to help ensure business owners pay tax rates more comparable to the corporate tax rate reduced by the TCJA. If allowed to expire, the section 199A deduction will be uniquely and severely disadvantage passthrough businesses. Of family businesses surveyed in our annual study, 78% operate as passthrough businesses, whether a partnership, LLC, S corporation, or other non-corporate structure.

4. Restore the full deductibility of research and development (R&D) expenses. The R&D deduction has historically been a bipartisan issue, gaining support from both parties in discussions on economically beneficial provisions to include in a 2025 tax bill. According to our family business survey, 22% of family-owned businesses are in the manufacturing/operations industry and 11% are in the construction/facilities industry, which rely heavily on R&D investment.

5. Restore 100% bonus depreciation. Next to their commitment to their employees, family-owned businesses rely on capital investments to compete, grow, and thrive. Bonus depreciation is a critical tool for family businesses to support their capital investments and finance facilities and equipment critical to their ability to grow, expand employment, and contribute to the communities in which they operate.

6. Preserve the capital-gains tax rate. Like the estate tax, the capital-gain taxes present an obstacle for capital formation and investments necessary for family businesses to expand, modernize, and succeed in an increasingly competitive market, with 13% of family businesses ranking it in their top three tax policies of concern – a 4% increase over the 2023 Survey.

7. Prevent the creation of a wealth tax. Wealth taxes – taxes on existing assets and unrealized gains – will be particularly harmful to family business owners who often disproportionately invest in the business in the hopes of passing it on to the future generations. In the most recent Family Business Survey, respondents identified preventing a “Wealth Tax” as one of their top five economic priorities – a concern that was nonexistent in prior years.

Top Of Mind Taxes

To further solidify thinking on tax priorities, this month we conducted a “spot poll” of 100 family-owned businesses on the topic of taxes in 33 states.

In this “Tax Policy Priorities Poll” we asked what their greatest tax concerns were right now, from increases in income taxes, to no increases in estate taxes, to restoring research and development expensing. The results showed the following percentage ranking for the top tax concerns by family business respondents.

The top concern was “No decrease in Estate Tax Lifetime Exemption,” which received 30% of votes from respondents, including those in the funeral services industry.

In a close second place, family businesses want to see “No Increase in the Income Tax Rate,” which received 28% of votes.

When it came to “No Increase in Capital Gains Tax Rate,” 13% respondents felt this was a top tax concern, while “Establishment of a Wealth tax” received 11% as a top priority. The “Wealth Tax” worry is trending upward.

Finally, such priorities as “Keep 199A Deduction for Pass Through Entity” worried 10% of family business respondents, while “Restoring R & D Expensing” got 4% of the vote.

Lastly, when asked the question about “Restoring Bonus Depreciation,” only 3% replied this was a top priority.

Let Congress Know

Nobody knows what Congress, or the new White House, will ultimately agree on when it comes to taxes, or how they will manage the growing gap between revenues and expenses, but everyone agrees there will be a new tax bill in 2025…good, bad, or ugly. The only way to state your case is to voice your concerns. The Congressional Family Business Caucus Meeting was held on Sept. 18 and in the meeting addressed pass-through taxes, enterprise structure, and possible wealth tax legislation.

Pat Soldano is the President of Family Enterprise USA and the Policy and Taxation Group, both nonpartisan organizations advocating for family enterprises of all sizes. They are the organizers of the Family Enterprise USA Annual Family Business Survey 2024 and assist in organizing the Congressional Family Business Caucus.

What leadership lessons have you learned from the previous generation that you rely on today?

What leadership lessons have you learned from the previous generation that you rely on today?

What leadership lessons have you learned from the previous generation that you rely on today?

What leadership lessons have you learned from the previous generation that you rely on today?

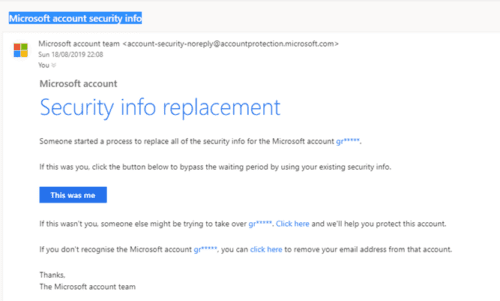

How to Manage the Risk of Cyber Attacks

How to Manage the Risk of Cyber Attacks

We had the pleasure of speaking with Ben Kuncaitis from

We had the pleasure of speaking with Ben Kuncaitis from

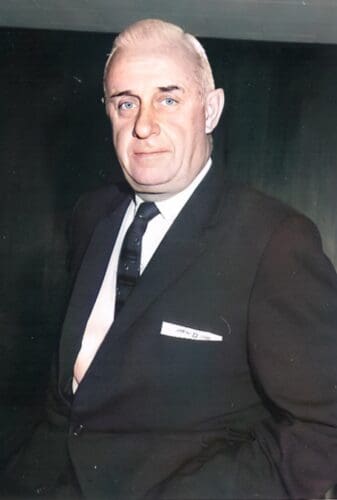

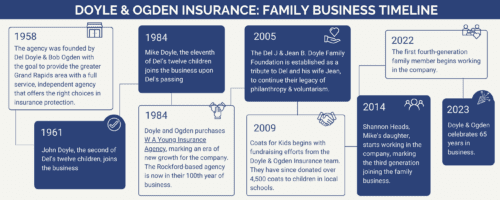

All photos are courtesy Doyle & Ogden. The interview has been edited for length and clarity.

Family Business Alliance strives to help family businesses with the tools, resources, and connections to help businesses succeed. Learn more about our resources including

All photos are courtesy Doyle & Ogden. The interview has been edited for length and clarity.

Family Business Alliance strives to help family businesses with the tools, resources, and connections to help businesses succeed. Learn more about our resources including

Business Group. Maintaining the same name, values, and customer service, WM Uniform is carrying the family’s legacy and team forward through the partnership.

Business Group. Maintaining the same name, values, and customer service, WM Uniform is carrying the family’s legacy and team forward through the partnership.

Family Business Alliance strives to help family businesses with the tools, resources, and connections to help businesses succeed. Learn more about our resources including

Family Business Alliance strives to help family businesses with the tools, resources, and connections to help businesses succeed. Learn more about our resources including

family business’s most important contribution?

family business’s most important contribution? Over the last year, SecurAlarm has embarked on a business model shift, which we are still in the midst of. We are shifting our focus from products to services because we believe security is so much more than technology and transactional relationships.

We want to align technology, procedure, and training unlike any other security integrator out there. We want to deliver personalized, comprehensive, and strategic plans and solutions to our clients, who we think of as partners. So much change is required, and it will be a long journey, but we know it will allow us to better serve our team and clients for another 100 years. Why the shift? It goes back to our Why, of course! We Care, So We Protect.

All photos are courtesy SecurAlarm.

Over the last year, SecurAlarm has embarked on a business model shift, which we are still in the midst of. We are shifting our focus from products to services because we believe security is so much more than technology and transactional relationships.

We want to align technology, procedure, and training unlike any other security integrator out there. We want to deliver personalized, comprehensive, and strategic plans and solutions to our clients, who we think of as partners. So much change is required, and it will be a long journey, but we know it will allow us to better serve our team and clients for another 100 years. Why the shift? It goes back to our Why, of course! We Care, So We Protect.

All photos are courtesy SecurAlarm.

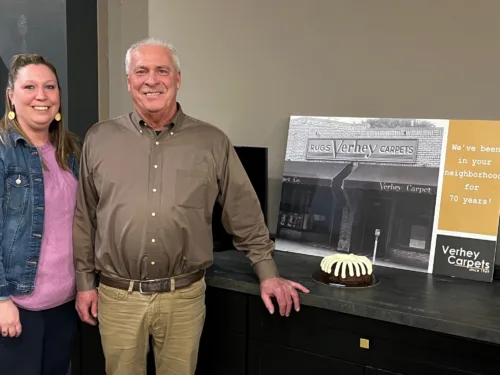

This feature is part of our Member Anniversary Program. For more information or if you are interested in exploring opportunities to be featured, please email aislinn@fbagr.org.

Family Business Alliance strives to help family businesses with the tools, resources, and connections to help businesses succeed. Learn more about our resources including

This feature is part of our Member Anniversary Program. For more information or if you are interested in exploring opportunities to be featured, please email aislinn@fbagr.org.

Family Business Alliance strives to help family businesses with the tools, resources, and connections to help businesses succeed. Learn more about our resources including

in the last 10-20 years.” When Allison was a teenager, they began offering wedding services again and Ludema’s continues to expand and connect within the West Michigan Community.

in the last 10-20 years.” When Allison was a teenager, they began offering wedding services again and Ludema’s continues to expand and connect within the West Michigan Community.

Before joining, Alan worked for a few notable local, family-owned corporations, including Steelcase and Bissel as a financial analyst. “I knew it was time for a new opportunity.” It was at that time that George approached him with a job offer. “We’ve been talking, and we might have a job for you at GL Resources.”

Alan notes it was the first time they had discussed him joining the business. “I was very excited about it. Working here was always in the back of my mind, but I wanted to build up other experience and learn from other companies first.” Although the business was not founded on the premise of passing it down, the family expressed that having the second generation involved has given them a transition plan.

“It’s a cool little business, and we felt if we could transition the business with Alan, it could go on another 40 years. If you don’t, it ends.”

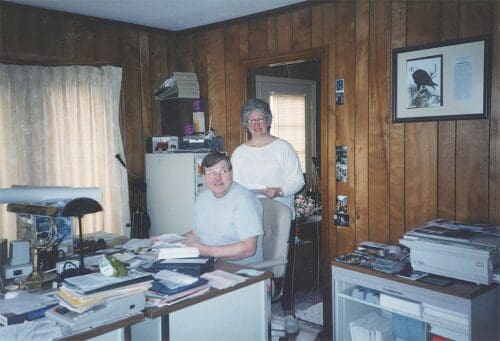

Joanie, who serves as President, has been there since the beginning. After having their first child, she officially began working for the business. Beforehand, she had a career as an accountant, so managing the bookkeeping for GL Resources was a natural progression. Initially a spousal-run family business, George and Joanie’s differences also became their strength as owners and partners.

“I came from a very structured business environment,” says Joanie. “So, I tried to bring that structure here, but it took a while for us to figure out how best to do this.” As a “details person,” Joanie is now responsible for many of their organizational processes, formal structures, and general management. Conversely, George is the risk taker, so Joanie’s influence allowed him to focus on sales and vision.

Bringing in the second generation has helped professionalize the business in various ways, as is typical transitioning from the

Before joining, Alan worked for a few notable local, family-owned corporations, including Steelcase and Bissel as a financial analyst. “I knew it was time for a new opportunity.” It was at that time that George approached him with a job offer. “We’ve been talking, and we might have a job for you at GL Resources.”

Alan notes it was the first time they had discussed him joining the business. “I was very excited about it. Working here was always in the back of my mind, but I wanted to build up other experience and learn from other companies first.” Although the business was not founded on the premise of passing it down, the family expressed that having the second generation involved has given them a transition plan.

“It’s a cool little business, and we felt if we could transition the business with Alan, it could go on another 40 years. If you don’t, it ends.”

Joanie, who serves as President, has been there since the beginning. After having their first child, she officially began working for the business. Beforehand, she had a career as an accountant, so managing the bookkeeping for GL Resources was a natural progression. Initially a spousal-run family business, George and Joanie’s differences also became their strength as owners and partners.

“I came from a very structured business environment,” says Joanie. “So, I tried to bring that structure here, but it took a while for us to figure out how best to do this.” As a “details person,” Joanie is now responsible for many of their organizational processes, formal structures, and general management. Conversely, George is the risk taker, so Joanie’s influence allowed him to focus on sales and vision.

Bringing in the second generation has helped professionalize the business in various ways, as is typical transitioning from the  “Alan has really opened our eyes to be more forward thinking,” shares Joanie. Navigating generational differences when working together is inevitable in family run organizations, but the Snyder family has thoroughly enjoyed working together.

“Alan has really opened our eyes to be more forward thinking,” shares Joanie. Navigating generational differences when working together is inevitable in family run organizations, but the Snyder family has thoroughly enjoyed working together.

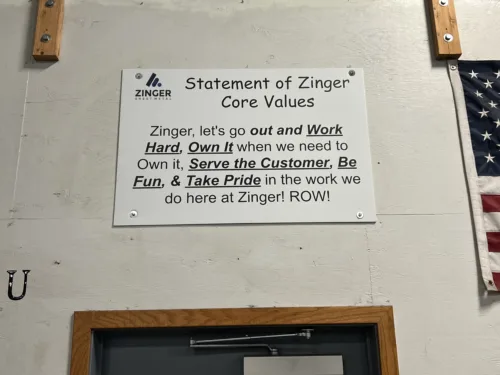

1. What are our core family values and how do they impact our success?

1. What are our core family values and how do they impact our success?